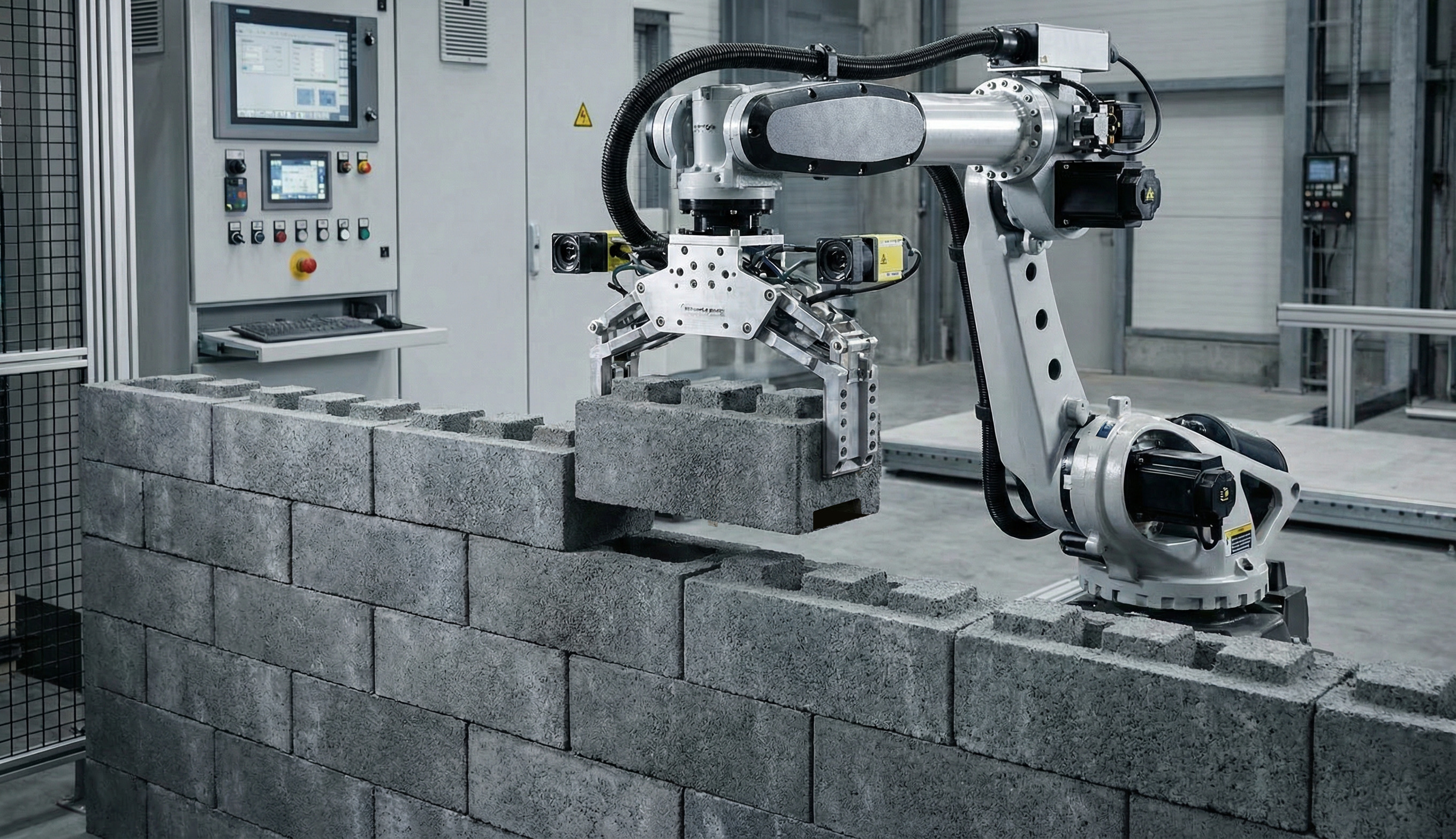

Industrial Robotic Arms

Automated manufacturing precision bringing consistency and efficiency to mass-scale interlocking brick construction.

Method Overview

Industrial robotic arms bring factory-level automation to construction, executing precise brick placement with unwavering consistency and speed.

These programmable systems can be configured to follow exact construction blueprints, placing each interlocking brick with millimeter-level accuracy. Multiple robotic arms can work simultaneously, dramatically increasing throughput on large projects.

The standardized nature of interlocking bricks makes them ideal for robotic handling, as the consistent dimensions and interlocking mechanism enable reliable automated assembly without the variability challenges of traditional masonry.

Key Advantages

The benefits of robotic automation in construction

24/7 Operation Capability

Robotic systems can operate continuously without breaks, fatigue, or shift changes, maximizing construction productivity around the clock.

Millimeter Precision

Computer-controlled movements ensure each brick is placed with sub-millimeter accuracy, eliminating human error and alignment issues.

Mass Production Ready

Scalable systems can handle high-volume projects, making robotic assembly economically advantageous for large developments and prefabrication facilities.

Enhanced Safety

Removing workers from heavy lifting and repetitive motion tasks significantly reduces workplace injuries and associated costs.

Consistent Quality

Every brick is placed identically, ensuring uniform structural integrity and aesthetic appearance across the entire construction.

Other Assembly Methods

Explore alternative construction approaches for your project