Manual Assembly

Traditional hands-on construction approach utilizing skilled workers for precise brick placement.

Method Overview

Manual assembly represents the foundational approach to interlocking brick construction, relying on human expertise and craftsmanship to create durable structures.

This method is ideal for small to medium-scale projects where flexibility and adaptability are paramount. Workers can make real-time adjustments, handle unique architectural features, and ensure quality through direct observation and touch.

The interlocking brick system's mortar-free design makes manual assembly particularly efficient, as workers can quickly position and secure bricks without waiting for curing times.

Key Advantages

Why manual assembly remains a preferred choice for many projects

Low Investment

Minimal equipment costs make this method accessible for projects with limited budgets or in areas where heavy machinery is impractical.

Flexible & Adaptive

Workers can easily adapt to site conditions, handle custom designs, and make on-the-spot modifications as needed.

Ideal for Small Projects

Perfect for residential builds, renovations, and projects where the overhead of automation would exceed the benefits.

Skilled Labor Utilization

Leverages local workforce expertise, supporting community employment while ensuring quality craftsmanship.

Reduced Training Requirements

The intuitive interlocking system requires less specialized training compared to traditional masonry techniques.

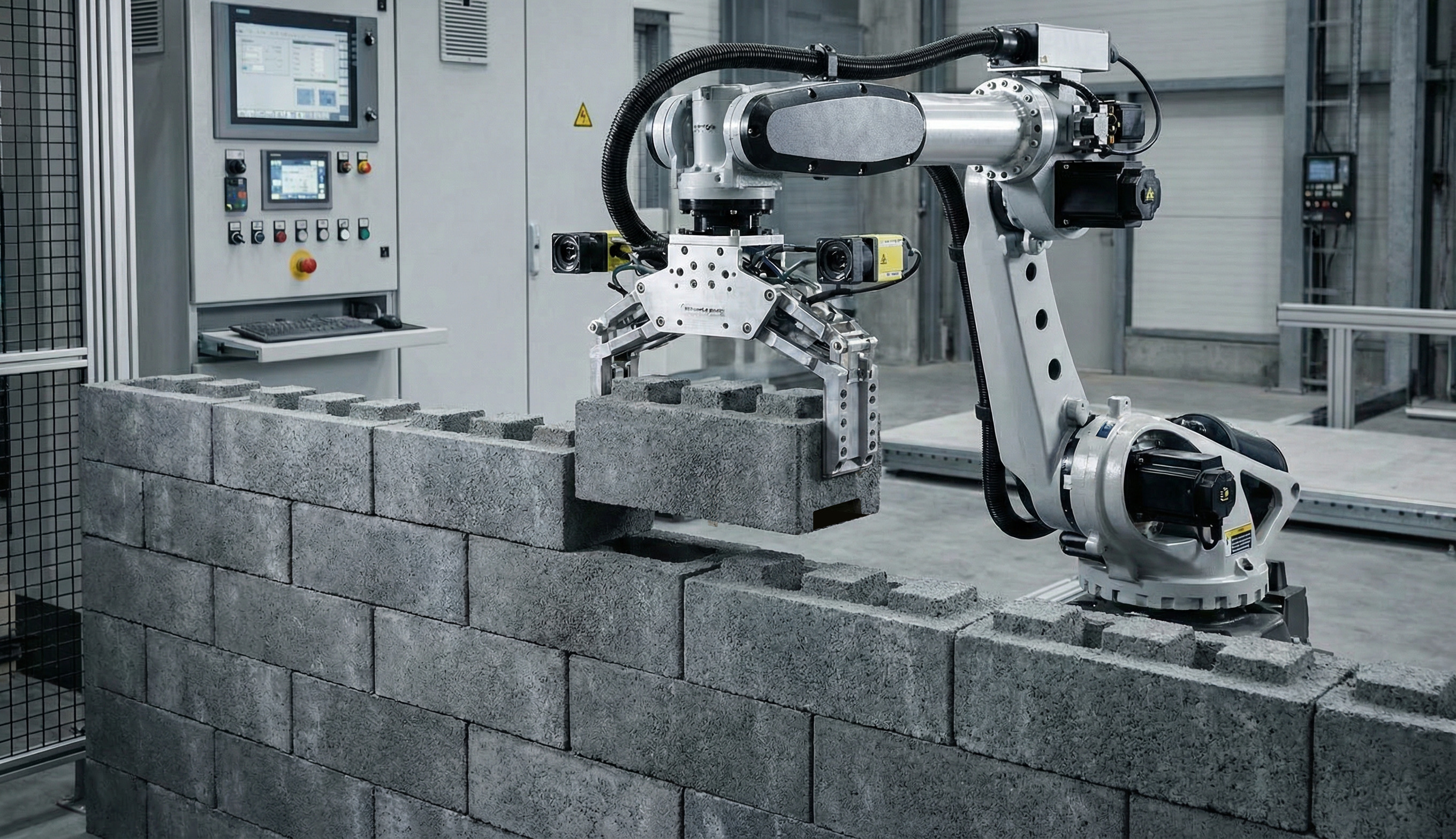

Other Assembly Methods

Explore alternative construction approaches for your project